Hot keywords: Electric welding machine lithium battery

National Service Hotline

National Service Hotline

+86 18912673551

Functional characteristics

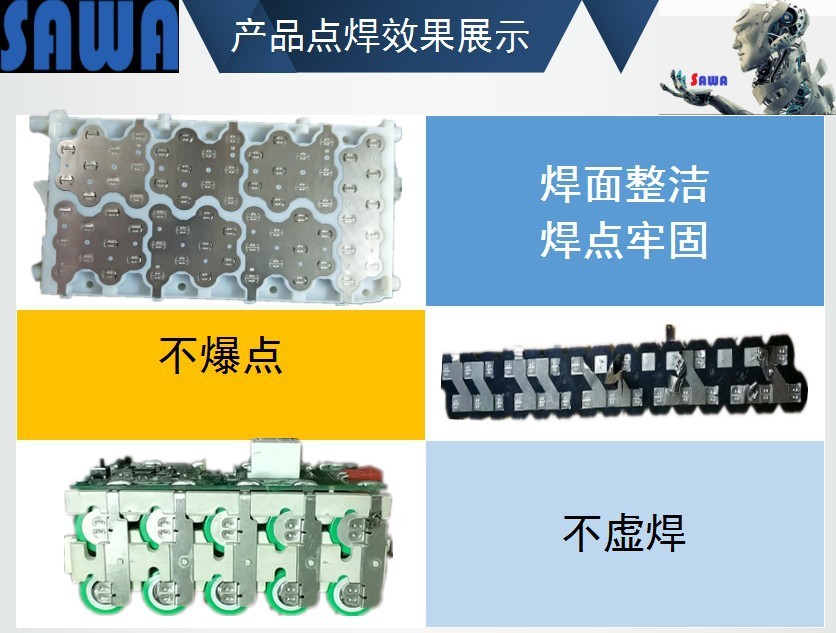

1. Equipped with current and voltage welding monitoring alarm, effectively solving virtual welding and explosion welding phenomena

2. When positioning the servo motor, ensure accurate and stable spot welding positions

3. The machine comes with a power off or breakpoint welding function, which allows for arbitrary adjustment of position for spot welding

4. Abnormal clamping alarm, no welding workpiece alarm, no current alarm shutdown

5. One click calibration function for overall displacement of solder joints, which can calibrate point displacement caused by changing solder needles or other reasons

6. Optional automatic scanning start

7. After scanning the code, bind and store the welding data

8. Can increase the rotation of the welding head by 0-180 degrees

9. Sharp needle and convex spot welding universal chuck

10. Welding data recording

11. Can be connected to MES

12. Needle grinding function can be added

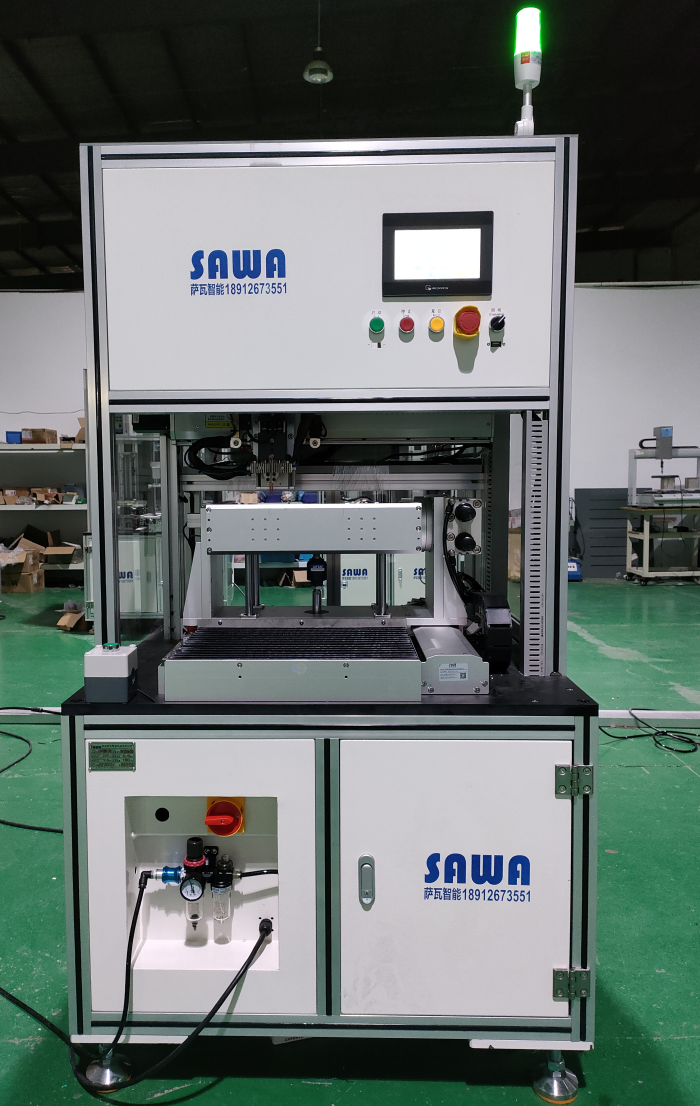

Suzhou Sava Intelligent Technology Co., Ltd. was founded in April 2007 and is located in Zhangpu, Kunshan City, Suzhou. It is a high-tech company that integrates research and development, design, production, sales, and service. The company is committed to new energy lithium battery automation equipment; The research, design, and manufacturing of automatic spot welding machines, automatic sorting machines, visual inspection, automatic cell support machines, automatic screw locking machines, automatic soldering machines, tooling fixtures, and fully automatic PACK production lines. The company has an experienced and technically strong design team that can provide customized industrial automation solutions for customers. Our solution is based on the concept of lean production, combined with automation control technology, to assist customers in achieving continuous improvement, continuously improving quality and efficiency. Sustainable provision of excellent machinery and technical services to customers.

Suzhou Sava Intelligent Technology Co., Ltd. was founded in April 2007 and is located in Zhangpu, Kunshan City, Suzhou. It is a high-tech company that integrates research and development, design, production, sales, and service. The company is committed to new energy lithium battery automation equipment; The research, design, and manufacturing of automatic spot welding machines, automatic sorting machines, visual inspection, automatic cell support machines, automatic screw locking machines, automatic soldering machines, tooling fixtures, and fully automatic PACK production lines. The company has an experienced and technically strong design team that can provide customized industrial automation solutions for customers. Our solution is based on the concept of lean production, combined with automation control technology, to assist customers in achieving continuous improvement, continuously improving quality and efficiency. Sustainable provision of excellent machinery and technical services to customers.

Service hotline